All Activity

- Past hour

-

GuyMontag started following 1972 Bulova President "E" Sea King 11ACACB movement

-

Movement holder made with 3D printer

Waggy replied to LittleWatchShop's topic in Manufacturing Tools with 3D Printing

Good idea, working on it.... - Today

- Yesterday

-

No problem with this steel breaking its a perfect working material, the difficult bit is figuring out where to put the detent on the spring. Yessss, at last not a watchmaker but a part maker. Its not perfect, i made 2 mistakes . I made a guess where to put the detent on the spring and i made it a bit too deep and the other was the drill bit caught a wobble on when i tried to open up the post hole 2 tenths. But it works perfectly with a solid click on crown set position so I'm well chuffed. Not sure what to do about harden and tempering it, seems to have a good spring action in its annealed state, do i leave it as is ?

-

Mike27298 joined the community

-

Thanks. Very helpful. What a cool and talented and helpful group/community! Well done -- and much appreciated!

-

1971 Bulova Accutron Spaceview 214

ManSkirtBrew replied to ManSkirtBrew's topic in Your Current Projects and Achievements

-

All right! Back together, cased up, and ready to rock and roll. Well, after I cased it and forgot the seconds hand. And then after I found a fitting back gasket. And then after I had to take it apart again because I forgot to put the automatic rotor back on. I did find a vintage Hadley Roma strap in red leather, as an homage to the original maroon strap. I'm super pleased with how it looks. Can I say chuffed as an American? I may polish the case at some point, but for now I'm just gonna wear it. And of course, pictures. First dial up, dial down, and on the wrist. Including the cat tax.

-

Just a note for those who come searching for information on this topic in the future. I did eventually find the Mark's video on how to replace these springs, as someone observed, he does in fact make the replacement look easy. (It actually is relatively easy once you have the knack of it.) If you're enrolled in one of Mark's online courses, the demonstration of how to replace this spring is in the Bonus Videos section of his course site, and is called "C2B1 – Sea-Gull Style Shock Springs".

-

If the metal was twice as thick, it wouldn't snap so easily. The thickness is governed by the space available so you can't use thicker metal. If you glued two pieces together, the likelihood of snapping would be reduced. That's my theory anyway, could be wrong.

-

there are various approaches to learning watch repair. A lot of people want to jump right in and every single watches something to be repaired restored. But other times like this it's disposable it's here for you to learn and when you're through learning you throw it away. yes you definitely should try this you have a learning movement you need to learn and the best way to learn is by doing something.

-

If I can’t re-pivot the wheel, the logical thing to do is to descend the pivot hole. Plan is to either stick a suitably sized hole jewel (from a barrel bridge or something) or fashion a blob of epoxy on the underside of the escape wheel cock so the wheel sits on its one pivot on the base plate and the staff with the broken off pivot (which I’ll polish as best as I can) becomes the upper pivot. As long as it doesn’t foul the 4th wheel it should work? I know it’s a bodge job, and if this were a rare movement, or belonged to someone else I would not do this. I’m just interested to see if I can get the thing to run.

-

Movement holder made with 3D printer

GuyMontag replied to LittleWatchShop's topic in Manufacturing Tools with 3D Printing

I'm curious if the base diameter could be changed so that it could be used with the hand press tool, which I believe is 31.0 mm. -

eltrecee joined the community

-

Help identifying GP calibre : Girard Perregaux 17 jewels

Gilles replied to Gilles's topic in Identify This Movement or Watch

25.9mm Thank you, it looks like a match ! -

I'm not with you there Rich .

-

Boggie46 joined the community

-

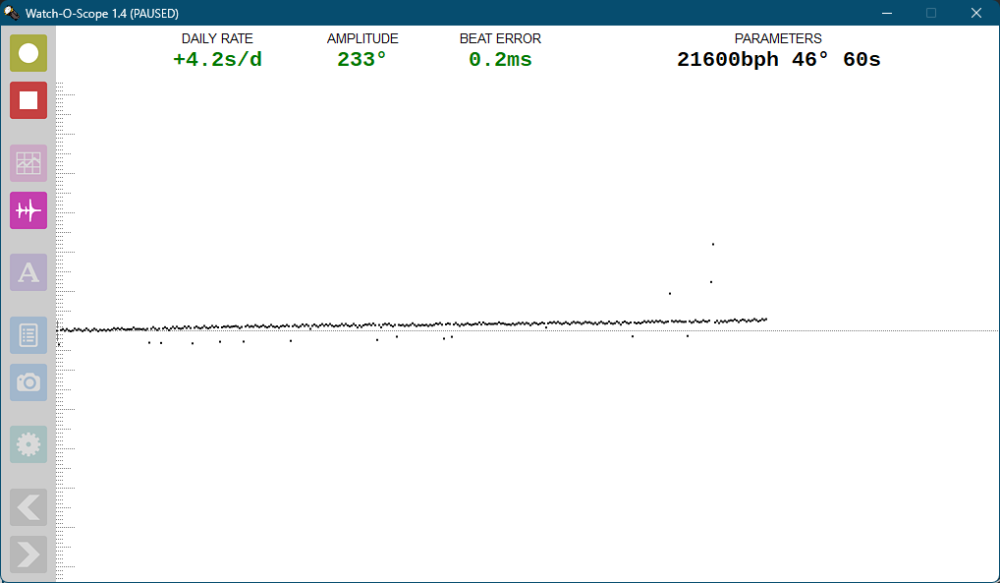

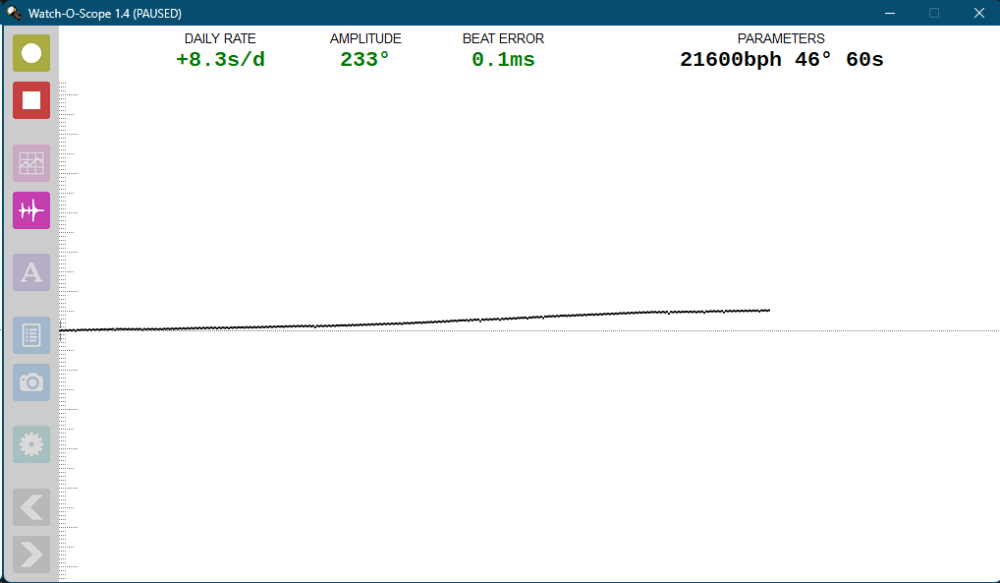

Hello everybody, sorry for the late reply. Thank you all so much for your help and your tips. I got lucky and found a replacement wheel bridge for cheap which actually ended up being in decent condition. I decided not to do anything about the mainspring barrel pivot since I didn't have the right tools and the barrel didn't have much endshake anyhow. I am happy to report that the watch now runs great, I have regulated it to about +-10/s day which is fine by my standards. The timegrapher result looks decent as well, although beat error is around 0.6ms which could be better I suppose. Amplitude reaches over 230 quite consistently which I'm happy with also. My lighter fluid has also been replaced by balance spring cleaning solution and now the springs don't stick to themselves anymore - who would have thought. I'm super happy with this watch, it might not be worth a whole lot but it's awesome that I could restore it and it makes me wear it with pride. To me it's a genuinely good lucking watch, it'll be my daily driver for a while. Thanks again to everybody for their input! I couldn't have done the repair without your help. Here are some images for those interested, the bracelet isn't original but I don't really mind:

-

Balance-hairspring system is oscillator with big Q-factor. When all in the movement is OK, the rate (frequency) is verry close to the own resonant frequency of the balance-hairspring. But in some cases, the movement (with foult) will force the resonator to work on pritty different frequency, sometimes faster, and sometimes slower. When this happens, the amplitude is always weak. So, the first thing to ask is what is the amplitude. If it is more than 180 and the hairspring doesn't touch itself and anything else, then for sure it is 'short'. If the amplitude is weak, then the first thing to do is to understand why and rectify the problem. At this time no point to check timekeeping. But, if one doubts that the hairspring is not correct, then He needs to calcullate the rate of the movement, then to 'vibrate' the balance-hairspring out of the movement and to measure the free oscillations frequency (period) with timer in order to ensure that they comply with the rate. If we have pictures, then it will be easier to tell something about that wheel.

-

Landeron 248 setting eccentric studs

Klassiker replied to Jon's topic in Your Walkthroughs and Techniques

So much work has gone into this! Thanks again @Jon. I will go back and check my adjustments from last weekend. A few questions for you, if you don't mind. In the reset position, I can understand the problem if the gap between the hammer and the minute counter heart is too big (slide 77) but what is bad about both hammers being in contact with the cams (slide 76)? I read somewhere that Landeron recommended grease on the runner cam, but the minute counter heart should be dry. Is that so, and why? How many tads in a ligne? -

Difference between AS 1686 and ST 1686

BlueHarp replied to BlueHarp's topic in Identify This Movement or Watch

Many thanks for your replies! -

RichardHarris123 started following Setting lever spring

-

Could you glue two pieces together for rigidity and separate after forming?

-

watchweasol started following Is this a 'hack' ?

-

Hi. Sounds like a problem clock, can you post some picture# of the clock and the parts in question please. Thank you

-

The first broke while i was using a dremel to shape the jumper spring at the join, i guess you call it the fixator, the disk grapped hold and flicked it off . The second time same place but while i was filing. This steel feels more malleable, it is annealed steel. Working out the detent on the jumper is a real. pain in the butt.