Search the Community

Showing results for tags 'atmos'.

-

I have been watching videos on the repair and servicing of Atmos clocks and I'm intrigued. I have so far serviced three 400 day clocks, which look very similar. I think I'm ready for an Atmos clock. So before I blow $1000 on a low end Atmos clock, I have some questions. I'm just wondering how much more difficult is it to service an Atmos clock? Are there any special tools and jigs required? Can the ethyl chloride that we see being used to treat football injuries on the field be used to refill the bellows? Any advice and words of wisdom are desperately appreciated. Thanks in advance.

-

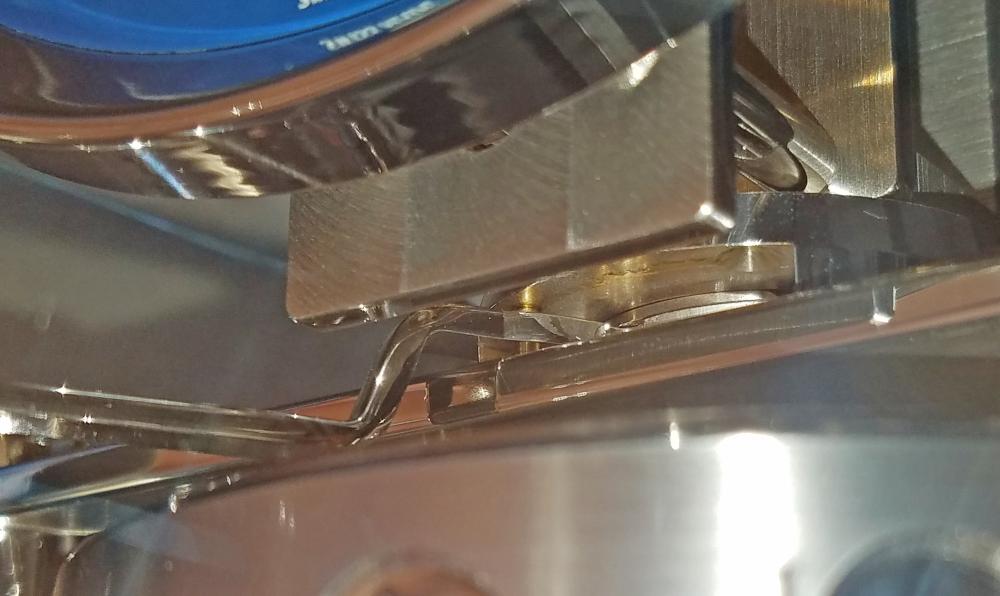

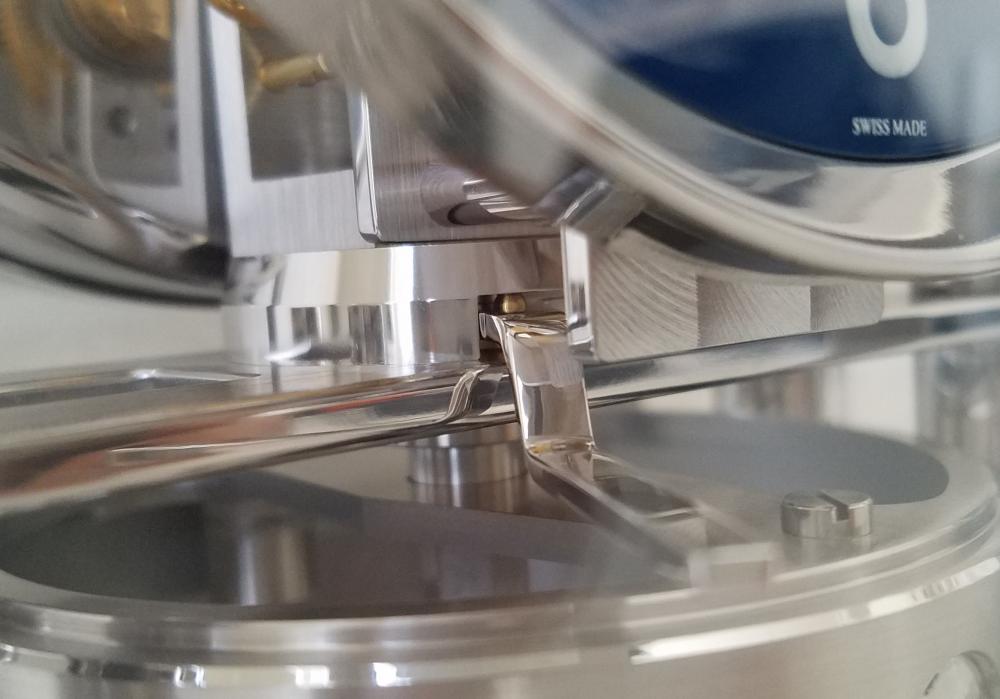

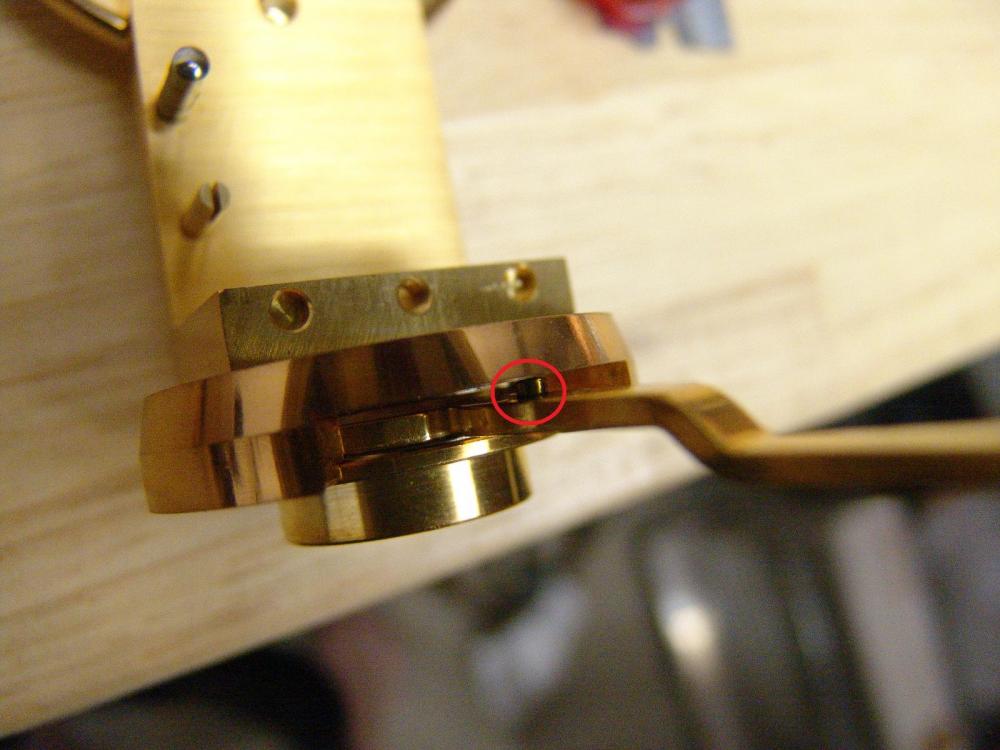

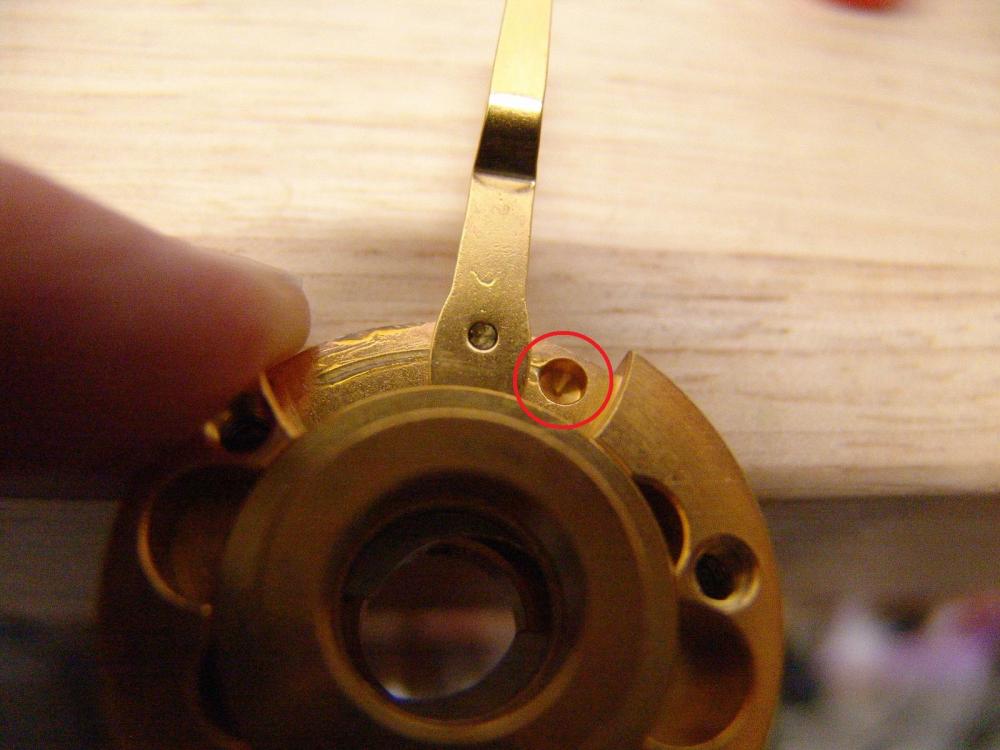

As a first time Atmos owner, I was taken aback by the amount of force it required for me to slide the balance lock from right to left to initially unlock the balance after i had made sure the clock was perfectly horizontal via the bubble.the manual was not specific enough and i really don't know how much leftward force is required?!?furthermore, the manual said to "...press downwards a little and the slide the lever to the left to unlock..."i could not feel any difference when i press the lever downwards a little. it was as though nothing changed when i pressed it downwards. as a result, i had to simply slide the lever to the left.it was not a smooth action at all! it was a great deal of friction, and took a good amount of force. i didn't know if i were doing something wrong or that amount of force required was intentional by design so as to secure the balance??at almost the far left of the lever's movement (almost to the farthest left part), the balance became "loose" and freed. there was a "CLUNK" sound and the balance sort of became loose with some degree of dropping sound, like as though it was dropped maybe a few millimeters! i was startled as i knew the tiny wire (vertical hairspring) is very delicate so that "CLUNK" was scary. that plus the amount of force required to slide that unlocking lever were totally not described and unknowns to me. may i ask how much force it requires to slide the lock from lock to unlock (sliding it left) in general? is it a very smooth action? or is it an action that feels like there's friction as you slide the lever from right to left? since it then started (after the lever is moved fully to the left) without any further action on my part, and then now at around 3 days later, it is keeping good time (thus far), might you think it is ok or might you think there's damage?may i ask if my experience is normal? or did i goof and did something wrong and might have hard my brand new 560 Atmos? the manual is very opaque on this point. also, pressing down is not a very sure thing as i pressed down and i didn't feel much of any flex at all on that lever, so i started moving the lever left without any downward pressure.i think i might have DRAGGED that rounded hemisphere and might have DUG a groove along the underside where you see that dragged arc in your 2nd picture!how much harm have i done, may i ask?my fear is that dragging it might have done some irreparable harm!! furthermore, at close to the very end of the leftmost side of the lever's position, i see and hear a "clunk" sound when the balance is "released" and started danging freely. it was a "clunk" sound that is more than what i was hoping for, as i know the fine Elinvar wire is very delicate. May I ask if it is normal for the release at the very end (far left of the lever's position) to include such a release sound and almost abrupt motion? i was hoping that it wouldn't DROP the balance, even for a few millimeters.the good part is that now at 3 days after the initial setting up, it is keeping very good time.whether or not there is a groove DUG into the underside of that brass piece as the lever was traveling from right to left is an unknown to me at this point. disappointed at JLC's manual and at myself. but still, i'd like to know if i did anything wrong to educate myself.thank you in advance.

-

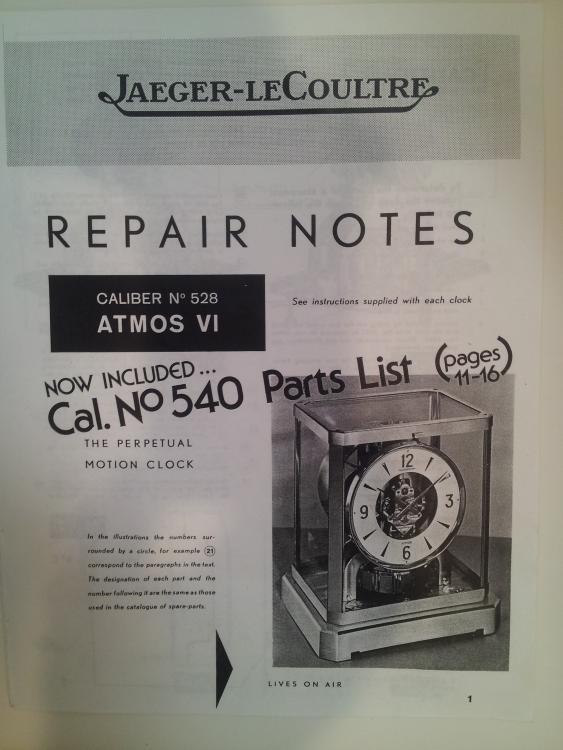

This is my Atmos cal 528 story circa ~1960 – its been years that I’ve put my eyes on Atmos clocks looking in its beauty and clean / sharp looking as well as their technical structure. In the country where I live, I’ve never saw any Atmos clock new or pre-owned for sale therefore I decided to buy on Ebay. At that time, I didn’t think that I’ll have to fix it I just want this “furniture” at my saloon. When unpacking the clock at home, I figured out that the chain is broken. I can’t tell if this happened due to shipment or it was originally broken but no matter - it was broken and here is where the adventure starts…(broken chain means winding mechanism is out of order). As watch/clock hobbyist, there was of course only one option – jump into it, ignoring those who claims that even the experienced and professional clockmakers shouldn’t touch Atmos without the proper skills and knowledge. I’ve started to read the available material on the WEB, spending time to understand each and every step. I bought also the repair PDF notes with explanations and dedicated tools like hands remover since without it, you will damage the minute pivot. Repair notes: Hand remover: Also, I couldn’t find a proper screwdriver since for some reason, the standard screwdrivers blades are 0.6mm or 0.8mm while this screws require 0.7mm blade. Important to mention is that without perfect fit, the screws will be damaged and if there something I hate is to see those signs on the screws because of using improper screwdriver (or sometimes due to non-skilled hands). Therefore, I took 0.8mm and resized it to 0.7mm. Also, need to say that this screws are having a large “cap” so once they are tightened, they are very difficult to be removed. One of the screws: Another mission was to get new chain but this was found easily online. It took me about 5 month to complete the study and buy everything. Before I started the work, I did few inspections looking for other potential issues: 1) I manually wind up the spring to the desired tension (according to the spec). I found the clock is running although the amplitude was lower than the spec (spec is 360 – 540 deg). 2) I checked that the bellow is functioning – measuring at room temperature and after refrigerator. It looks that bellow is ok In order to replace the chain, I had to remove the dial, bellow, motor, front plate and the main spring. I didn’t disassemble the balance system as in my inspection, it was looking functioning properly. I disassemble the motor gears and cleaned the holes. I also disassemble the mainspring and cleaned it and oil it. It looks that the clock wasn’t serviced for a long time. There are only few points to lubricate the clock. Most of the friction points must not be lubricated! Then I installed the new chain following the instructions of the required distance between the ratchet and the bellow to allow the optimal torque for the windup process. Then, I’ve put everything back and wind-up the main spring manually to its base level means that from this point on, the bellow will wind-up the mainspring according to the thermal changes and the power that ran-out from the spring. The clock came back to life and I was able to monitor the mainspring winding up properly. This can be done by following a moving red point located on the barrel arbor ratchet winding system. The chain and the red dot: The clock is running ~2 years keeping excellent time after this service however, the amplitude is about 330 and even less, while the spec requirement is 360-540 deg. I’m trying to look for the reason but so far I didn't found. There is still work to do but so far I’m really proud of it. This is just beautiful, I hope you like it: