Leaderboard

Popular Content

Showing content with the highest reputation on 05/02/17 in all areas

-

Well after a year of building my skills and discovering good tools vs bad, I finally have a workspace that is comfortable and large enough to lay out all of my tools properly. A lot of advice I gleaned from Mark and this board so thanks to all Sent from my iPhone using Tapatalk3 points

-

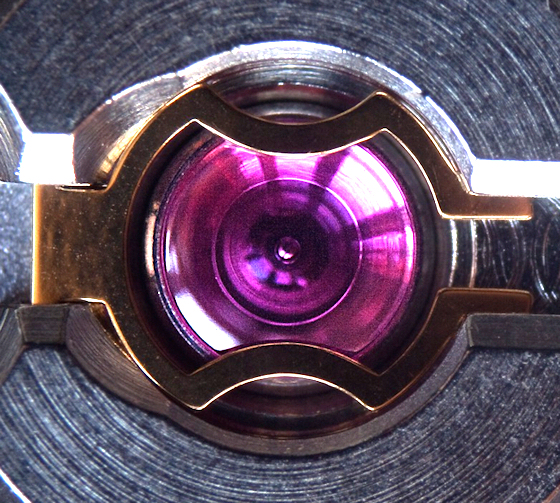

I've got a movement that I think is magnetized. The hairspring coils are sticking and it makes a compass needle jump when placed over it. Here's a pic of the timer reading: I've watched Mark's videos and so I'm shopping for a demagnetizer. I'm looking at the Etic for about $80 shipped, the similar C&H model for about $30 shipped, the generic clones for $10 or so from China, this bad boy from Amazon (too heavy duity?) and some vintage Vigor demagnetizers. I'm a little (a lot) tool nutty and I hate buying really cheap and then spending again for one that works. Any recommendations? Also, just for fun I was playing with the super slow speed function on my camera last night and made this video. Not great quality, but may be of interest. https://youtu.be/JpLEB0kiHw0 Thanks, Don1 point

-

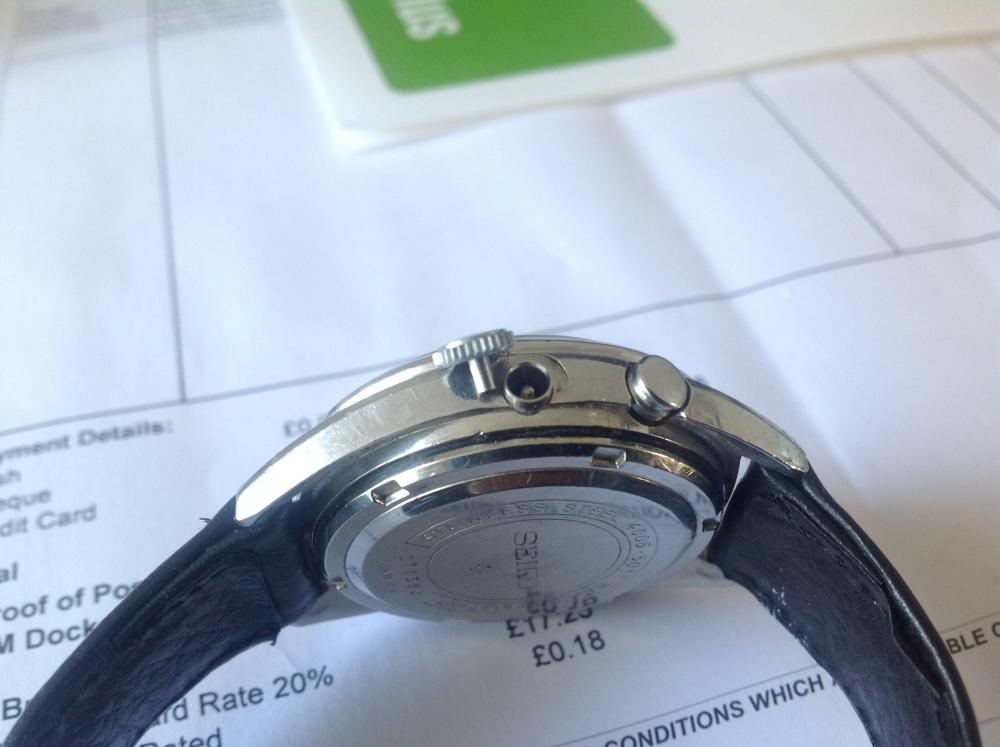

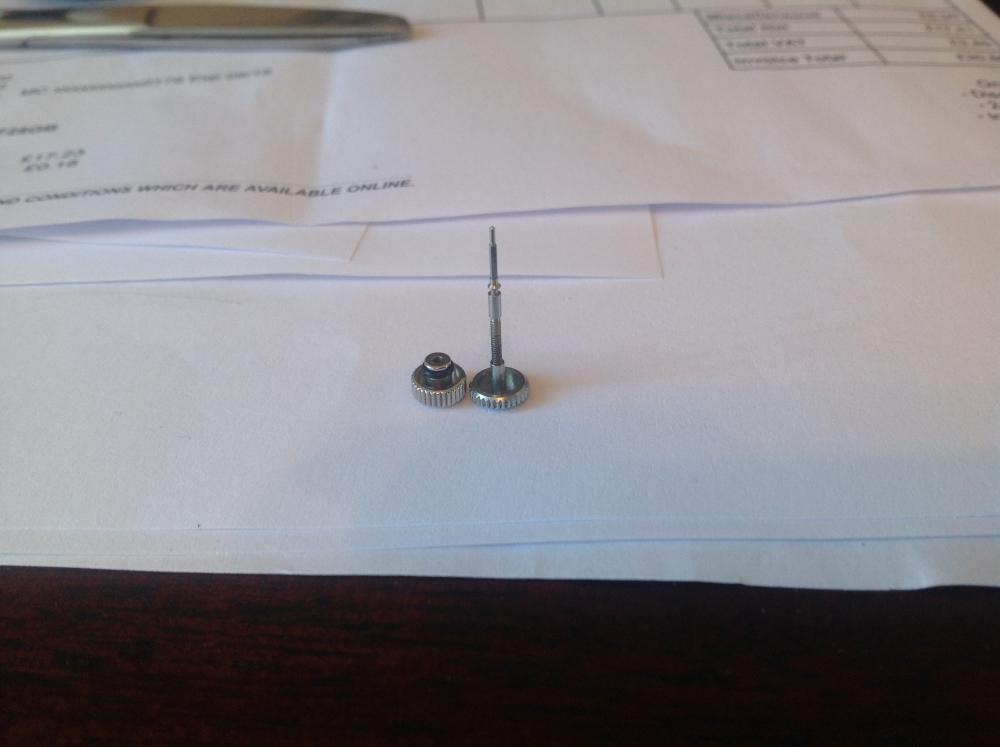

Well after some consideration I finally shelled out for a beaten up old Bell-matic. It is probably the most complicated watch I have, up to now, that I willl have worked on. It is not too bad I suppose but after bidding on about five of these watches i was surprised by the price they command even in poor condition. This is the pic from the bay Now that I have it I find the dial is not in bad condition at all, I accepted that the plexiglass was bust and it would need a new one (from Cousins) and the case has some need for buffing. However, despite being described as being in working condition there are quite a few faults. I found the crown was decidedly non standard and when wound backwards simply wound off and it transpires that it is in need of replacement. I thought I was in luck when I found one for £2.88 in Cousins but my hopes were dashed when the crown supplied proved to be the wrong tap size being 10 or 11 and not Tap 9 (10/100 mm) which is needed to fit the 354805 stem. Here is a pic of the crown that came with the watch - it is patently wrong. Here is a pic of the crown from Cousins alongside the other crown and it is obviously a better match to the tube and the gasket comes with it. Unfortunately the tap size was wrong but to give Cousins their due they contacted Seiko who confirmed I needed a 55M22NS1 crown (now obsolete) and they had supplied the wrong part and Cousins gave an immediate refund but did not ask for return of the Crown which I consider to be good service though I have now got my fingers crossed for the Plexiglass and gaskets I bought. Well thats my latest project. I am minded to drill out and re-tap the crown as in every other aspect it seems a perfectly acceptable crown. I may have to get some different taps though as the ones I have are a bit problematic on their lead in for the depth of metal to the dead end I will be tapping. I am in no doubt that there will be a lot of work here, the pointers look grubby and I suspect the spring for the alarm is faulted, though I heard the alarm work for a brief couple of seconds - it will need a full service but there are a few teardowns on the net - Christian has done one I could follow and I have found some more - luckily it seems to be a popular watch. Spares are available some easier to get than others but i will have to open it up and find out as I go along. That leather strap is revolting but it is the least of my jobs, date does change with pusher and the alarm ring does move and finally it does tick. Buffing the case should make a difference. Here are a final two pics - that is the best pic of the face I could manage through the bust plexi. I joined a Bell-Matic forum in another place (SCWF) and have accessed a shedload of info and spec sheets (grateful thanks to JohnWN) that will be handy. Just as an after thought heres a pic of some of my current favourites. The little Gradus needs some work and has seen some knocks but I will get round to it one day. I have a couple of cases with other stuff in ranging from the sublime to the ridiculous that I may get round to posting "some day". Bye for now - Cheers, Vic1 point

-

It most likely seems like a mechanical thing (wheels, levers, etc.) but I don't have experience with quartz movements in general and I can't tell for sure whether a simple lack of lubrication or some left over dirt from dried out oil is the issue here...1 point

-

I needed a portable mat for working at home, and find that the polyurethane foam sheet from UK store called Hobbycraft works well. It has a foam surface, so it will pick up dirt, but nothing is damaged by it, nor bounces off it, and it rolls up and fits in my box.1 point

-

Picked up this lot of 15 vintage men's watches of the Bay last night and I can't wait to see them up close. I was mainly interested in the Cyma and a handful of others as my beautiful wife-to-be is a deco and vintage fanatic! For $50 US, delivered, I don't think I went horribly wrong here. Considering the price of tuition nowadays, it's a bargain. Anything stand out to you folks? C1 point

-

I understood that buffing is a different technique compared to polishing. If I am correct, buffing "moves" the metal while polishing removes it1 point

-

I use these (A&F) and they work fine for me https://www.cousinsuk.com/product/antistatic-bench-mats1 point

-

I covered my work surfaces with this USA supplied Alvin http://www.madisonartshop.com/vyco-31x10yd1.html?cmp=googleproducts&kw=vyco-31x10yd1&gclid=CMKdhLjih9ECFQeDfgodpugOrw The in the actual workstations following a recommendation from Mark, I got non-slip Bergeon 7808-N black mats.1 point

-

1 point

-

Hello Vinn, I agree, the drivers must be sharpened to fit the slot but also finished off by flattenning the sharp end of the "Wedge" so that the flat part is in maximum contact with the bottom of the slot and the sides just about touching. It is a painstaking process that has to be done on each size of screwdriver. I have bought Bergeon replacement driver heads rather than do it myself as although I can do it, I am quite lazy though I do "dress my blades" which is not a major bit of work and you usually follow the original design of the blade. The Bergeon replacements are provided in the condition that I try to emulate when forced into adjusting a driver myself. Most of my instruction on such matters was gained from a book "PracticaI Watch Repair by "Donald de Carle" under " Essential Tools" I would never attempt hollow grinding on a small, say .5 mm or any small screwdriver, quite frankly think that reduction of the metal available would weaken the blade considerably. In fact to be honest, I have tried hollow grinding only once, on a 2 mm blade under magnification and life is too short. Having said all that I honestly believe that it is a personal decision and everyone should do what they want to do, if wrong decisions are made you soon realise and move on. Either way this forum is a great place for a frank friendly exchange of views that for an amateur tinkerer like myself has been really useful. Cheers, Vic1 point

-

I've got the chinese weichi 1000, nice and basic but it works, I got mine from amazon, felt I had abit more buyer protection ( thankfully I had as my first one went belly up) my second one is flawless and very handy, and shows people what their watches are running like before I attack them and then afterwards.1 point

-

I’m working on mechanical wrist-watches for two years now and in this time I came very often to one problem concerning watches with a regulator arm. I wanted a watch to run a little bit slower or faster (let’s say 3 seconds), so I had to push the regulator arm a very little distance. On many of my watches these arms have quite a big breakaway torque, so when I increased force and the arm started moving, it jumped a bigger distance than I wanted it to do (of course this led to a timing “correction” of 20 seconds, not the 3 seconds I wanted). Not my idea of regulating, this is just “try and try again, good luck”. Searching some forums on the internet for a tool to do this better I didn’t find a solution for me. So I had a close look at the regulator arms of my watches, did some measurements and finally built this little tool. The tool head grips over the regulator arm while the watch is on the timegrapher and due to the tools long lever arm (which is about 4 inches) I can manipulate the regulator position very precise. Here are some pics of my work on a Rolex 5513 with 1520 movement. The watch ran constantly +4 seconds per day and I wanted to slow it down to +1 second. No problem with the Delgetti-key.1 point

-

I have some Moebius D5 I bought from Cousins last year. It's a 20ml bottle which I'm unlikely to finish in my lifetime, let alone between now and the end of April 2017 which is the shelf life expiry date of this batch. I haven't been able to find a clear answer to just what the expiry date means for the oil in the bottle. Does it mean the oil should no longer be used from that date? Does it mean that if you use it at the end of the shelf life period the oil will do its job for another two or three years in the watch? Either way, as a tinkerer I'd be content to use it for the next couple of years. That would still leave me with more D5 than a hobbyist would ever need, so I'm planning to keep 2ml and I'm offering the rest of the bottle to other tinkerers in either 1ml or 2ml doses. I have some new small 2ml glass bottles, an unopened syringe and a blunt mixing needle to decant the oil without contamination. You can have it for free, but I'll provide my paypal address in the package if you want to make a voluntary contribution to the P&P. If all of the oil is taken I'll post an update in this thread. PM me with a postal address and tell me whether you would like 1ml or 2ml.1 point

-

Wow! If everyone were this generous, Moebius would have to lower their prices lol! PM Sent1 point

-

1 point

-

Just purchased a vintage demagnitizer and it did not work. So into the guts I went. I disassembled the demagnitizer and found that one of the power leads that was previously soldered to a plate had detached. So to repair it, I drilled a hole in the plate and prepped the cable (cleaned) into the hole; then soldered it into place. It now works. Discount on next purchase:) Sent from my iPhone using Tapatalk Pro1 point

-

It was made before electricity Sent from my iPhone using Tapatalk Pro1 point

-

Yep I have both sizes, and a nice sharp razor blade to trim them down for the jewel holes1 point

-

Like a proud father, I feel the urge to show off my latest creation. We recently moved to a new house which finally gave me the space to have an office/workshop. I have been working on a tiny little homemade bench the past few years and have been dreaming of a proper bench. Sadly the ready made ones I wanted are way out of my league. My design goals were: Affordable versatile Free standing (i rent the house and cant drill bolts into the walls) Sturdy I got the original inspiration from Dan Spitz. http://danspitz.com/for-sale/ His concept is to make stunning workbench tops. You then supply the legs. However at £2,000 for the top, there was that budget thing again. I did however steal his idea (I don't actually know if he or someone else came up with it) of the routed groove along the edge. It has already proved to be a godsend in terms of catching small screws, and the odd tool. I decided to add a perspex screen on the back and down one side as I am notoriously rubbish at not flicking click springs etc across the room. So, the basics. Worktop: 40mm solid Beech kitchen work surface from Ebay 2000mm x 620mm - £85 Legs: Steel workbench legs from Machine Mart about £40 including shipping Bench support: 2 L shaped steel struts from an old Victorian bed. £5.00 from a salvage yard, cleaned up with an angle grinder then polished. Struts: 30mm square steel tubing from steel merchant £20.00 Danish oil for bare wood: £5.00 (four coats on either side) £20 for bolts and screws. So I made the whole thing for well under £200. The top is extremely heavy and I haven't totally managed to eradicate minimal side movement and ideally I would bolt it to the wall but as I said I can't. Still it isn't going anywhere and I love it. Of course you don't have to make it 2m long but I wanted somewhere for my lathe. I am building a perspex divider to protect the workbench from cuttings from the lathe. Anyway, I hope it might give some of you some ideas.1 point

-

I have been using A&F screwdrivers for a few years and only recently purchased some Horotec. However the Horotec I shape the tips (see pic) using their sharper which gives a better grip on most screws. So I now have two sets the A&F & Horotec. In my option the A&F are really good screwdrivers they just need dressing now & again.1 point

-

1 point

-

1 point

-

1 point

-

Hi Chris, That looks great. I like the lighting you use. Yes carpet is a big issue. I do have a good magnet actually, but I was taught quite a clever technique of putting a stocking over a dyson hand held vacuum. Works pretty well too. I need more drawer space too, which you seem to have plenty of.1 point

-

I agree with you. And some cuts are so shallow that unless the driver touches the bottom, no good grip is really possible.1 point

-

All I mean is to make sure the tip is perfectly flat. You don't want to sharpen the angles of the blade like a knife blade, to an edge. When you break a tip, you are getting into thicker metal the further up the blade you go. When you sharpen them, you need to do both sides of the blade at the angle which will thin it back out and then sharpen the very tip at a 90 degree angle, as flat as possible with a very fine stone, to get the width you need to match the screw head openings. That's all I mean when I use the term "blunt".1 point

-

This should put your mind at rest. Click on this link. http://members.iinet.net.au/~fotoplot/sdriver/sdriver.html1 point

-

This is what you need. If you get anything that is to powerful it can distort the hairspring which is the main part that needs demagnetizing. http://www.ebay.co.uk/itm/like/161822826949?limghlpsr=true&hlpv=2&ops=true&viphx=1&hlpht=true&lpid=122&chn=ps&googleloc=9045125&poi=&campaignid=207297426&device=c&adgroupid=13585920426&rlsatarget=aud-133395220866%3Apla-131843272146&adtype=pla&crdt=0&ff3=1&ff11=ICEP3.0.0-L&ff12=67&ff13=80&ff14=122&ff19=01 point

-

I have this one.. DSC09615 by Micky.!, on Flickr Its probably exactly what Bergen sell, but at a fraction of the cost, it even has Bergeon branding.1 point

-

If you can afford the Etic, then go for it - I melted mine by leaving it plugged in and mistakingly setting a book on top of it which pressed the button down :D I since purchased one of the Chinese ones to see what it was like and it works just fine. The Elma I have in my video is an electronic one and it is good but IMO seems to do no better than the cheap chinese one, it is just very convenient to use.1 point

-

The testing is done, the verdict is in. I have run the Zeiss - Eye Mag Pro F 5x @ 235mm (9.25inches) through their paces on many watches, including several Analog Quartz movements with very small gear trains. So what do I think? .... These are the BEST optics for working on watches bar none! I will never, and I mean NEVER, go back to using a standard monocular eye loupes again; except on inspections that require the extreme magnification of a 20x to 30x loupe ... which is rare. The clarity is so good that I don't even have to swap to a higher power loupe to locate the tiniest of pivots, even the tiny rotors in Quartz analog movements ... this set does it all. I have shown them to several professional watchmakers, who have been in the trade for decades (some as much as 50yrs), and they are astounded by the Eye Mag Pro's clarity and comfort, and are looking into getting themselves a pair. Believe me when I say there is nothing like working with stereo vision that moves with your head movements, and gives complete depth perception at all times. If you can afford to buy them, DO IT! And if you can't afford to buy them .... SAVE! :)1 point