Leaderboard

Popular Content

Showing content with the highest reputation on 03/28/17 in all areas

-

I think I've located the crown & stem that you need. Since yours is a UK model, I don't have an exact reference, but I believe that I have found its American cousin, 26760. As far as I can tell the cases are the same. The Timex part number is 025-060054 The crown and stem can be found in the material system 401/1 TX1K, listed as compartment 10. I've attached some pictures, and if you want it just send me a PM and I'll mail one off to you.2 points

-

Hey all, Here is my first Service Walkthrough for servicing the Favre-Leuba 253 movement. I found it easier to do this in a word processor and save it as a PDF rather than trying to make it into a giant post. I hope that's ok. I welcome any and all constructive criticism of the document. FL_253_Service.pdf1 point

-

Anyone been watching "The Repair Shop"? BBC1 at 6.30pm - yesterday and today so far. Various experts, including a clockmaker, repair various bits and pieces. Good watching.1 point

-

Hi folks. Sorry I have not been on much lately. I have uploaded the Service document to Google Drive. Hopefully this will allow everyone to get to it again. Here is the link: https://drive.google.com/open?id=0Bw4CFczC5vh0XzI0TjVTRDQzaWc Please let me know if you have any issues accessing it.1 point

-

I've been looking for a long time for one of these, and this popped up on the bay without much of a description, it was clearly being sold by someone who didn't know much about it, from the photos, it looked like a 7750 movement holder to me, so I took a gamble, and was pleasantly surprised when it arrived, in perfect working order, but above all, it sure is for the 7750 movement DSC07931 by Micky Aldridge, on Flickr DSC07934 by Micky Aldridge, on Flickr Think I may put it through my ultrasonic bath to remove the staining as its clear its been sitting unused for some time. All the pushers, pivot holders, and screws are free, so will remove those prior to that and grease them. Next movement holder I want to get it the dedicated 7753 holder, probably get that from Boley.1 point

-

1 point

-

1 point

-

Thank you very much @noirrac1j, this is great information to have! I had imagined the naptha being a solvent was more for dissolving oils, etc. C1 point

-

I would wear a mask and disposable gloves no matter what I read on the internet.1 point

-

The joys of pocket watches Dave. Another common fault with pocket watches is broken balance staffs probably because most had no shock proof jewels. Getting replacement parts is really difficult.1 point

-

1 point

-

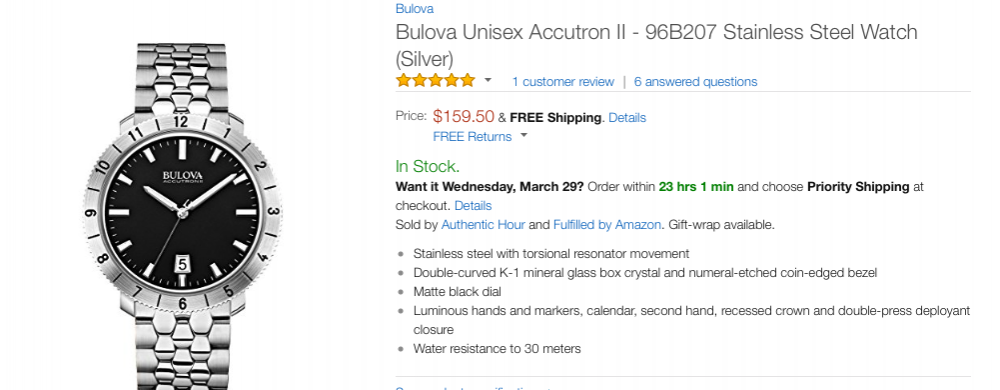

The post office just delivered this Astronaut ll . I got it to compliment my collection of my two other Bulova Astronauts . Bulova has seen to install three different types of movements for each . My first Astronaut is a vintage Accutron with the 214 Tuning fork movement . My second is the Automatic Buzz Aldrin signed limited edition version . And my latest is the Astronaut ll with the Very accurate Precisionist movement ,...what a smooth second hand . Here's a look at the second hand's sweep...... I chose the economical blue model with the blue textured leather strap because of its simplicity that seems to highlight the smooth second hand's sweep . Not a bad price at all.... And you have an option . Black dial and SS coffin link bracelet ,...at yet another deal.... From 2014... And the Watch...1 point

-

Hey @Wesley881 welcome to the forum. I would not recommend using naptha in an ultrasonic cleaner. There really isn't any need for it because the purpose of it is to dissolve old oils and displace any water. The concentrated detergent gets rid of any biological grime and dirt (also solubilizes grease), and that is what benefits from ultrasonication. Plus I don't think is a great idea to breathe in that much fumes from naptha. I use concentrated detergent with water I heat to about 90 C, 3x rinse in warm water followed by wash in naptha. After that I let most parts air dry with the exception of the plates, cannon pinion and drive gears: those I dry by gentle blowing with compressed air. Everything is dry and ready to assemble within minutes. The hairspring assembly and the pallet fork get separate baths in one_dip followed by gentle drying with compressed air. I've not had any problems and I've done all types of momenteverything from cheapy BFG and EB movements, to Omega, GP, Bulova, ETA, FHF, and Seiko. J1 point

-

Rolex, Cartier, Omega and Breitling all do courses, you need to do coar$e for each brand before they will supply you parts. Depending on your level of ability and presuming your Quality of work is to their standard they can accredit you to different levels. Rolex have an accreditation to be able to 1) dial exchanges and battery and reseals. 2) The above and service all watch's apart from sports models. 3) The above, including sports models apart from complicated models like the Daytona and Yahtmaster 2. There is also a Daytona coar$e you can go on once all the above accreditations are achieved. Cartier have an accreditation but is very limited, it basically shows you how to Refurb a case and do movement exchanges, once accredited you can only get seals and case parts and then send the movement in for exchange, they are in the process of introducing a coar$e in Switzerland for people that have the current movement exchange accreditation which I think will mean they can actually get movement parts once it's done. Omega do a one week accreditation coar$e which means you can get all parts including parts for the co axial watch's. This automatically gives you access to Rado, Longines and Tissot parts but only if you purchase the brand specific tools for each brand. Breitling also do an accreditation but again depends on your ability, Some people can only do Battery and Reseals, some people can only access Quartz and basic automatic parts and the full accreditation means you can do chronographs, nobody can get parts the the emergency watch. All of these accreditations are subject to a workshop inspection that meets certain criteria for each brand. A lot of the main big equipment can be used for multiple brands like polishing machines, timing machines(apart for co axial), cleaning machine, ultrasonic, dryer, ect, but all brands insist on lots of specialist case tools, movement holders and hand tools, not to mention oils, polishing compounds, etc, which are all very expensive and are mostly only available from them. Your workshop must be up to their spec and if you don't buy the tools they won't supply you parts even if you have past the course.1 point

-

I would stay away from steam because of the heat, more than because of the water. Watch parts are not meant to be exposed to intense heat, I'm not sure how the different metals will react. Some of them will expand more than others, resulting in parts that end up out of alignment. If you're on a budget, use lighter fluid (and a small paint brush for tough dirt) to clean the parts, and then 99% alcohol to rinse and remove any moisture (except for balance wheel and pallet fork). We're talking a $20 investment that will last you a decent time.1 point

-

Hey! Welcome to the club I am sure we had all a similar start. In addition, for us hobbyists a small success has a much greater value than for watch repairers who have learnt the trade in a school or by an experienced master. I hope You did not discarded the tangled spring. It would be a nice practice piece making it to shape again. I have some hairspring repair videos if interested. https://www.youtube.com/watch?v=x7i9VrMkFaA You could check if the main problem is the bent pivot by turning the movement over. If it has different rate/amplitude/working hours in the different positions, then one of the pivots is significantly bent. The pivot can be bent back if it is not looking to bad. There is a special tool for this, but i am using jewels in old abandoned watch main-plates for this purpose. Just put the pivot in jewel where it just fits and bend the wheel so that it will lean the same degree in all directions. One can bend it by hand, the tool is just to makes sure one would not make an accident and to hard bending. To practice repairs i am using big old pocket watches as Oldhippy suggested. Search for ramps333 on e-bay, he has always a lot of old non-working movements. Or for newer ones i would buy movement batches from India.1 point

-

WOW! I had no idea there were so many different types! Now if each of you could send me just a tiny little drop of each clearly labeled....thanks! LOL1 point

-

Thanks for the kinds words guys. Glad you all like it. I have more to come for sure. If anyone is interested in the arrows I used for lubrication markers, here they are: Photoshop Format https://drive.google.com/open?id=0BwTSe2ImNk_qeW1wQU5mV25Kb0k&authuser=0 GIMP Format https://drive.google.com/open?id=0BwTSe2ImNk_qdGR3Y1F4a1F0amc&authuser=01 point