Leaderboard

Popular Content

Showing content with the highest reputation on 03/13/17 in all areas

-

3 points

-

Last night whilst reassembling a Felsa 1560 I fired the Return Bar Spring from the keyless work across the room, 45 minutes of searching failed to find it. I'm now about to spend £5.81 plus £2.88 postage to get another one from Cousins. It was bound to happen to me sooner or later, just hope it doesn't happen too often.2 points

-

And now for something completely different - We got this gem for our son for Christmas, and he loves it. Unfortunately, he reported a problem with it, which I just diagnosed to a missing tooth on the hour wheel - resulting in Mr. Cleese going lame around 8:00. And no, it's not a product of the Ministry of Silly Watches... actually it comes from the Unemployed Philosophers' Guild. Note the "For best results use other side" notation on the case back. The watch uses a pretty basic Miyota movement, so here we go searching for a replacement. Cheers, Gryf2 points

-

Welcome to the Club! Did you try the vacuum approach? - vacuum the carpet then go through the dust bag? Magnet approach? - trail a magnet on a string over the area? Or did you fall on your knees, cursing creation? - that sometimes helps!2 points

-

For your entertainment, watch disassembly in 45 seconds Sent from my iPhone using Tapatalk Pro2 points

-

I was doing a repair on an old German Pocket Watch that had a cracked jewel. The jewel was seated in the plate and rubbed in. Here is the shot. The first step was the push out the jewel which I did with my jeweling tool. After which I needed to fund a replacement jewel and rub it back in. So what I did was use a concave stake from my staking set and placing it over the edge of the volcano and rotating it slowly until the edges closed in. It worked. Sent from my iPhone using Tapatalk Pro1 point

-

I am new to watchmaking. So far, watchmaking for me has been 5% watchmaking and 95% excavation: I spent 12 hours vacuuming my carpet and sifting through the collected dust, for example, in search of a click spring I had assumed flew across my room, flung from the first watch I tried to reassemble a few weeks ago (an AS ST 1686). I would pour the same lighter fluid I use to clean the parts on the pile of dirt and hairs from the vacuum, then sift through the ashes, and repeat, determined to find that evasive thing. It got dark by the time I was ready to sift through the ashes the fourth time, and so I ran back inside to grab my flashlight. Upon my return, shining the light into the curiously empty pan, one of the guys from the motorcycle shop next door asked me "was that yours?" Luckily they had poured the smoking ashes onto the sidewalk rather than into the nearby planter. I tried not to look too upset or desperate, but fearing a passing pedestrian stepping on the pile and walking off with my spring lodged in their boot, I got down on hands and knees with the flashlight and my face inches from the smouldering ashes to continue my quest. Maybe they felt guilty, but hopefully just out of curiosity or familiarity the three big guys pulled out their cellphones, turned on the lights, and joined me. The next morning one of them asked me if I ever found that pesky thing, and I was able to tell him "yes, in fact I did find that spring in the last place I looked: right where it belongs: in the watch." See, when the click didn't engage, and any winding I did on the crown would immediately unwind, I realized the click was spring loaded, looked back at the photos I took step by step of the disassembly, saw the spring sitting there in the watch in one photo, and assumed the worst: that the spring had sprung its way to freedom. But after that exhausting day of excavation, I finally slept a few hours, and awoke with an epiphany: and sure enough, upon removing the mainspring winding gear, discovered hiding underneath what you experienced watchmakers probably knew was coming the whole time. The spring was where it should be, just on the wrong side of the click. Well, the good news is that the watch, soon able to hold a wind, ticked back to life and kept pretty good time.... of course, then I lost the watch (that's another story). I finally removed my carpet and painted my floor, but still managed yesterday to lose what I think might be called a date wheel blocking yoke for my first over $10 movement: an original ETA 2824 from a Technos Select I found on Ebay, which is how I found this forum and this thread. I thought it was the adjacent spring that hit me in the forehead (which I found on the table) but it must have been the yoke, which must have then landed in a crease in my pants or shirt and left my room before I knew it was missing. Argggg! I have one picture documenting the disassembly that shows that the yoke even existed. Now it's a ghost. Any advice on what the part is actually called would be highly appreciated. I can easily find the corresponding part on ebay for the 2824-2 version, but that looks different than my ghost yoke. I was glad to see that MrBeat found a spare, but was hoping to see the photo as DJT2 requested, to help clarify what I think I need. Thanks for any insight. I will be here often, hopefully to help eventually, and hopefully never again to identify a lost part. I am including a picture of my lost part (which in the photo lies between the U shaped spring and the date wheel) and, for your entertainment, the LOST WATCH poster I plastered all over Brooklyn after losing my first watch (which I did find by the way woohooo!!!!) [File uploads failing. I will try to post a followup with photos.)1 point

-

Just means it's been well used/loved! A replacement would be a good thing.1 point

-

Extra photo of a similar cal 1570 here: The ratchet wheel and click are the bronze coloured wheel at the bottom with the screw in the middle, and the clock sitting to its lower left. As Rogart says, you want to check that the ratchet wheel is turning when the rotor rotates. It will take many rotor turns for one tooth of the ratchet wheel to pass the click. It may be easiest to demonstrate to yourself its operation by first observing the ratchet wheel and click while slowly manual winding. Then rotate the rotor and check it also turns the ratchet wheel. Also, just for clarification of some of the comments above, you will not see the barrel move as it moves extremely slowly. The barrel is the section underneath the ratchet wheel, and it is the barrel which drives the train of wheels. The ratchet wheel turns the barrel arbor when winding, the barrel arbor winds the spring, and then the spring tries to unwind by turning the barrel which in turn drives the gear train. Maybe the terms "ratchet wheel" and "barrel" are being confused.1 point

-

Worth a read..... just for the chuckle [emoji23] Welcome Sent from my iPhone using Tapatalk1 point

-

I recently had a part take flight, and my search for half an hour was fruitless, all the time during the search I had my Optivisor on, slightly raised, it was only then, when I took it off, the missing part presented itself on the top of the brow of the Optivisor1 point

-

If you have time to read this, it might help. There are many different opinions of what constitutes a RR grade. I suspect this was due to the competition among mfgs for RR business. Mr. Singer is pretty knowledgeable on the subject. Lever set is RR okay. http://ph.nawcc.org/Railroad/Railroad.htm Your watch is nice 466 including gold screws and "high tech" regulator and well worn crown, did a quick search on elginwatches.org for more info.1 point

-

You will spend hours sweeping the floor and down on your knees and in some cases you won't find the part. Then one day its there and you will swear and cuss I did I turned the air blue.1 point

-

1 point

-

Okay, for those who notice nitty little details (as I think most watchmakers do) I am aware that the hands need to be corrected. My only excuse was that when I got around to putting on the hands it was towards the end of the day and I just wanted to case the thing and see how well it kept time. Haven't had the time to go back to it. Anyway, I titled this entry the way I did because it indicates something I love and the reason I entered watchmaking. For I found this watch in an old box (of old remnants thrown in free with some things I bought at a trade fair), lens-less, dirty (inside and out) with a broken mainspring. I replaced the lens and mainspring, gave the movement a good cleaning and did as much restoration of the dial as I could do with the primitive methods at my disposal; dial restoration being an art requiring far more time to master than I've so far put into the craft, but someday I hope to get better at it. As I said, the watch was in sorry condition and I felt sorry for it; as one might feel towards a waif on the streets, I decided to take it in some months ago as a practice piece. I mean, it literally had "cobwebs" in the movement; some kind of moldy stuff which I've seen in a lot of long--neglected timepieces. I put it through the cleaning machine and was pleased to see how it had brightened up and its quality began to show through--like a chronographical David Copperfield or Pip. I removed the remaining dirt with pegwood (Peggotty!) and Rodico and carefully oiled it. I was gleeful when, after final placement of the balance, the piece started to tick like a newborn baby come into the world. I, the parent, felt jubilant and, so far I haven't been disappointed as it is keeping good time, living up to expectations. I wear it regularly and someday maybe I'll come across a stray strap--lurking even now in some forgotten recess--that will do it justice. The watch is a 17j Elgin, with a gold plated case, as you can see. I haven't taken the time to look up the movement to see when it was made, but my guess is pre-WWII (any thoughts?). Would this have been a ladies watch? It's a bit bigger than most at that time. An unusual feature is the sub-seconds dial at 9 o'clock as opposed to 6 or 3. I may return to it someday when I am more skilled but it's still a joy to own.1 point

-

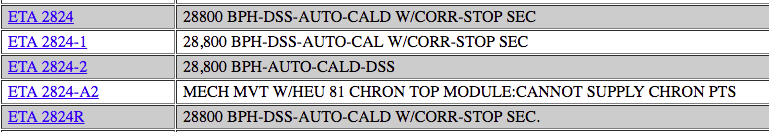

Glad to be of help Sal. Coffee would be great and I'll have some time in a few weeks when I finish up with school. I looked up the ETA on Borel and there are 4 variants to the basic module: Yours is only date, correct? It would be the 2824-1. The difference between these is whether it has the day and hack feature to synchronize the movement. There is also a chrono but that doesn't have parts available on Borel. I have account and can order if you need. Just PM me. J1 point

-

1 point

-

Love the post! It reminds me of my father, who was a watchmaker for over 50 years. Whenever I'd go for a visit he always had a story to tell. His stories would always start, "this doggone watch I'm working on..." or "I had this doggone watch the other day..." I was always fascinated by his stories. Although, to be honest, most of the time I had no idea what he was talking about. In retrospect, I understand some of them now. But he's long gone and so are his stories. So, I honestly appreciate you sharing your "stories" with us! Shirley1 point

-

1 point

-

1 point

-

I demagnetized the movement and adjusted the hair-spring as good as I could. Tested it Dial UP & Dial Down; Dial Up; Dial Down; Not sure if the "off line" dots are interference picked up by the W.O.S, but it's getting better ..... With my limited amount of handtools available, I can do no more for the Landeron and decided it was time to separate roads. It's back together again, all chronograph functions are working fine and it kept fairly good time during a 12hrs test with dial up. From a none-runner to a runner....... that's at least something I hope somebody will pick it up from where it came from and is able to give this Landeron the last push it needs for a 2nd life; I hope you enjoyed reading this restoration attempt as much as I did working on it Regards: Roland.1 point

-

Hello and welcome. Check out Marks videos on the Forum if you haven't already. There very helpful and he's a natural teacher Sent from my SM-T585 using Tapatalk1 point

-

1 point

-

1 point

-

Hello and welcome! There is tons of stuff on this site that can help someone to get started, and if you don't find what you are looking for, just ask!1 point

-

1 point

-

Welcome to this friendly forum. Lots of info on here for you, we also like photos, just ask if you can't find what you want.1 point

-

Welcome baggage1 to this friendly forum. Lots of like minded members here always willing to help & advise. Enjoy1 point

-

This project has got to the stage where I am getting glad it is over. Anyway, crown made, parts sprayed with clear laquer, acrylic fitted and strap fitted. A few other problems I had to deal with to get the watch keeping regular time. The watch now keeps good time and I will regularly wear it and see what snags come up (which I am sure they will !!)1 point

-

Hello @Endeavor, very nice thread. I chose a Landeron 248 movement as my first chronograph to work on. Right now it is completely disassembled and cleaned. For the re-assembling this thread is a perfect source for information.1 point

-

There are many options I can see here... 1. Keep hunting for the "right" part 2. Don't worry about the markings and swap for the good part you have 3. Solder in a bush and drill and tap to the right size 4. Use a slighly oversize screw... which you probably won't need a tap for as long as you run it in bit by bit, back and forth, with some oil 5. Punch the edges of the hole in the plate to close it up slightly as used to be done as a "quick fix" for a worn pivot hole Personally I would probably start at #4 if you have a selection of screws. If that fails, you can still try #5 then #3 in that order. If you don't have a tap, then taper the end of a spare screw slightly and file 2 flats on it to make your own. I'm sure othes will be along shortly with more opinions and ideas! S1 point

-

The time has come to repair the dial of my Nachtigall pocket watch.1 point