Leaderboard

Popular Content

Showing content with the highest reputation on 10/22/16 in all areas

-

4 points

-

That is a very large amount to blue without the correct equipment I would avoid. Just polish2 points

-

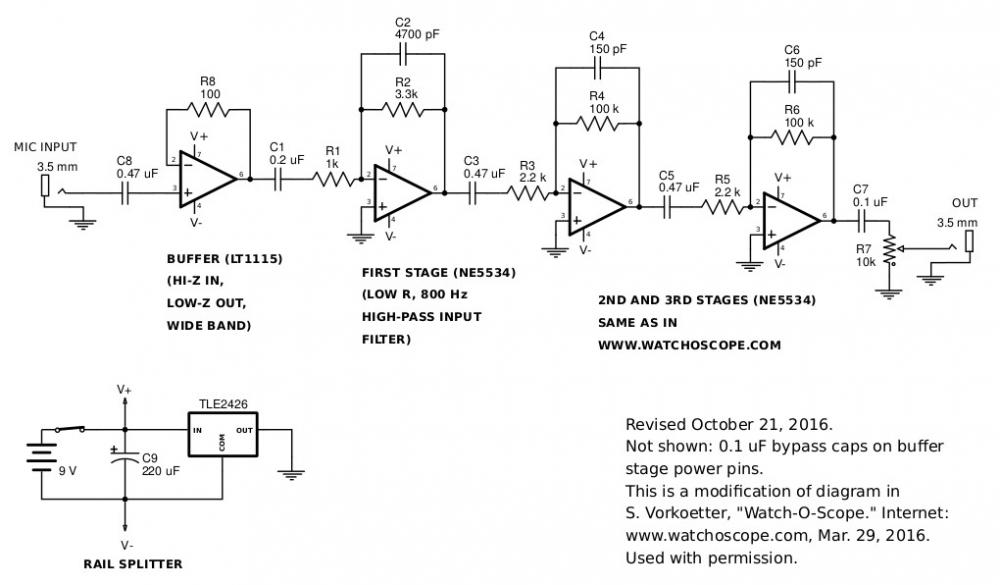

My previous attempts to lower noise in the preamp were flawed because I changed the bandwidth in doing so. The following circuit fixes this. There is an added buffer stage that uses an LT1115 op amp to isolate the microphone from the first amplification stage. Now the high-pass filter on the first stage does not depend on the capacitance of the microphone. I have it set for a frequency of 800 Hz (according to Stefan's comment of 800 Hz to 8 kHz being a good passband). I did not change the other high-pass filters to 800 Hz, but maybe I should have. The low-pass filters are all at 11 kHz, just as in the original Watch-O-Scope design. I built the circuit on my solderless breadboard. The measured noise was 6 mV, which should be compared to the 22 mV of the original circuit. I had a lot of trouble getting a buffer that was stable. I could not get the NE5534 op amp to work for this. It insisted on oscillating, even when I added the recommended 22 pF compensating capacitor across pins 5 and 8. My present circuit is still not perfect. It oscillates when the microphone (or signal generator) is unplugged from the input.1 point

-

well done it feels good when you achieve something I had the same problem till a asked the same question on here.1 point

-

Absolutely, clear coating with something...I'm not good at this though...so it would be interesting to see more solutions...1 point

-

I never use water...only L&R solutions, One-Dip and Lighter Fluid depending on what I'm doing...so, maybe it is the water?1 point

-

polish yes, but basic varnish will peel from metal. there might be some new clear paint, but its only a tool, vinn1 point

-

How about some light varnish in the outside to preserve it better? Maybe after polishing?1 point

-

welcome to the forum. i use to belong to that outfit. i enjoyed "setting up at the marts" vinn1 point

-

1 point

-

If the balance is completely out, then no matter how many balance screws you add you won’t get far. Start right from the beginning and remove all what you have added. Then start from there by gradually adjusting them, it might just be an adjustment to the original ones. Are you sure the balance is true and not bent. Also make sure the roller is correct and even all round not distorted in any way and impulse jewel is tight in its mounting and no rough edges and is of the correct size. There is also the possibility the hairspring is not compatible with the balance wheel. You could also make sure the staff is correct and not a replacement, check the fittings around the balance wheel and the staff I can’t think the treads from Russian pocket watches will fit an American pocket watch balance.1 point

-

Very nice work, thanks for sharing! Maybe you can carve your initials on that wallet!1 point

-

1 point

-

Normally the first four digits are the movement ID & the second digits are the case ID. That movement is now obsolete so finding a replacement is going to be difficult. I have attached a PDF of the movement which may assist in finding an alternative. Seiko 5Y22A - Technical Guide.pdf1 point

-

Watch Repair Talk it my favorite Seiko forum. Happen to have just received a new one myself, going to do a bit of light modification, will post results sometime.1 point

-

1 point

-

Hi Dave, There are at least 3 different stem thread sizes for the L48, so you will need some calipers to measure the diameter of yours. If you are ordering from Cousins in the UK, they convert mm diameter to tap size by multiplying by 10, but this is not a universal approach so be sure to check - as Bobm12 says, US suppliers use a different system. I did once find a conversion chart, but since I usually order from Cousins, I don't have much use for it. Looking at the case from your other thread, it has a case tube, but unlikely to be waterproof given the pusher type so you should be ok with a short or long pipe crown - a long pipe is good if the end of the stem has broken off. Typically you would fit about a 6mm diameter crown on a chrono. This should narrow it down for you: https://www.cousinsuk.com/product/short-pipe-chronograph-style-italian-ss?code=C44688 S1 point

-

1 point

-

1 point

-

I'm feelin' Retro today... I think I'll do a Double Header.. Starting off with a snazzy blast from the past with this water resistant Seiko 5 automatic 6119 - 5411 , ser. # 223055. I must like this watch because I wear it a lot . Very comfortable on the wrist . It was pretty shabby looking when I first got it , so I serviced it , cleaned the case and bracelet , Re-finished the case and put a nice satin finish , extended the bracelet with a spring loaded expansion link , and installed a new Seiko crystal . For the second half of the Double Header , up to bat is this Seiko 5 automatic 6119 - 6023 , ser. # 022685 . This one is a Sports Water70 Proof model . It "Sports " an inner rotating bezel . I serviced it , polished the hardlex glass crystal , gave the case a light polish , and finished it off with a rubber two tone band . Black with a blue accent on the edges to compliment tne dial .1 point

-

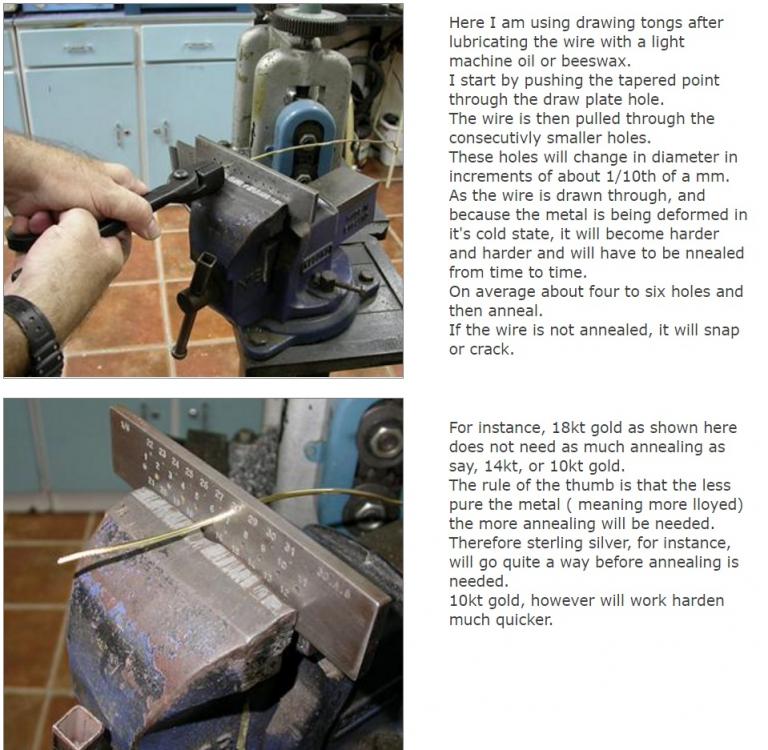

Most interesting indeed. I agree, its most likely a tool for sizing fine wire because it also appears to have a cutting blade at one end. Its French, Belge or Suisse. I suspect this one is French (see further down). The markings say " 63 trous" which is 63 holes, "garantie" which is guaranteed which I suspect refers to reassure the owner that the sizes are accurate. The holes are beveled and very small which is also interesting, they are for fine wires. I think its a jewelry draw plate : https://en.wikipedia.org/wiki/Draw_plate Here is how it is used: http://www.jewelry-tutorials.com/wire-make-your-own.html The "SHGM" identification on the tool is most likely the same of the company. Possibly an old watch or clockmaker company because SH would most likely stand for "Société Horlogère" I didn't see anything in the old Swiss companies: http://www.horlogerie-suisse.com/technique/l-ile-aux-tresors-horlogers/liste-des-marques-de-montres-suisses-vintages#s or modern listings https://fr.wikipedia.org/wiki/Liste_de_sociétés_horlogères, https://www.hautehorlogerie.org/fr/les-marques/ The cursive lettering on "trous" appears to be vintage pre WW2, definitely European. North American and British companies wouldn't bother with that type of additional work. It could be something from Morteau, in France which has a long history of making watch parts and tools: http://www.morteau.org/index.php?id=458 SHGM could stand for "Société Horlogère Générale Morteau". Morteau was a thriving watchmaking community well into 1960, it had over 250 watchmaking shops and 15 factories apparently things died down as tradesmen left for Switzerland « En 1960, se souvient-il, Morteau et ses environs abritaient encore 250 entreprises horlogères dont 15 manufactures. C’était la région de France où l’on comptait le plus de DS par habitant !Aujourd’hui ? C’est le désert. » Chaque jour, pourtant, 17 000 horlogers français passent la frontière pour aller travailler en Suisse. Rien que dans la vallée de Joux, berceau historique de l’horlogerie suisse, les Français occupent 4 000 postes de travail sur les 6 000 existants. Sans eux, ni Jaeger-LeCoultre, ni Audemars Piguet, ni même Patek Philippe ne pourraient honorer leurs commandes ! Comment ne pas profiter d’un tel savoir-faire chez nous ? http://www.parismatch.com/Vivre/Montres/Pequignet-La-renaissance-de-la-haute-horlogerie-francaise-235084 I think it may have been used for pocket watches before WW2.1 point

-

No, the 'tick' sound of a watch is actually a combination of five different actions and sounds from the escapement, starting with the impulse pin striking the slot of the pallet fork, next is the escape wheel tooth falling off the locking plain of the entry pallet stone and striking the impulse plain, third is the opposite side of pallet fork slot striking the impulse pin, fourth is the escape wheel tooth hitting the locking plain of the exit pallet stone, last sound is the fork striking the banking pin but there are as you can see lots of actions taking place to create the sound that don't include the banking pins. Hope this helps a little, the escapement is a fascinating subject. Brian1 point

-

Seiko 6309-5000 with internally faceted crystal. Crystal has had 6 stage buff and polywatch. New Old Stock crystal in parts bin for future use.1 point

-

I'm just now going though the section on mainsprings on Daniels's book. Fascinating stuff. Despite all the calculations there's no good way to determine which spring the watch will need when designing one other than some rough rules of thumb. It's way more technical than I need but fascinating for sure and highly recommended. Sent from my iPhone using Tapatalk1 point

-

Just noticed a mistake in my formula, corrected formula below length = Pi(inner radius of barrel squared - radius of the barrel arbor squared) / 2 * thickness of mainspring.1 point

-

Is it possible that the wrong screw has been used on the calendar wheel? Thinking out loud is it possible that too long a screw is projecting too far out the other side of the plate and just impinging on the spokesman of a wheel enough to take power but not stop the train. Then when the spoke clears the screw amplitude is restored until the next spoke.1 point

-

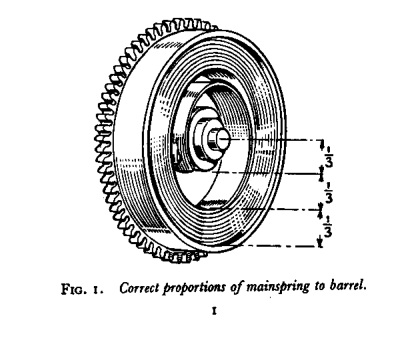

That's what I was told many years ago 1 third for spring, 1 third for arbor and 1 third for space.1 point

-

You beat me to it szbalogh I was just going through this last night at my watch repair course so its all thresh in my mind But to just add a bit more there are formulas that go into it deeper For example to work out the correct length of the spring is length = Pi(inner radius of barrel squared - radius of the barrel arbor) / 2 * thickness of mainspring. On average the thickness of the spring is around 1/100th of the inner barrel diameter. A very simple check you can do to see if the spring in the barrel is the correct one and not just one some hack found and stuck in is check the k factor. The k factor is the ratio between he radius of the barrel arbor core and the thickness of the mainspring. This usually falls between 10 and 14 k = radius of barrel arbor / thickness of the mainspring Bottom line, the spring in the barrel will be the best spring for the watch unless some hack has fitted an incorrect spring at some point.1 point

-

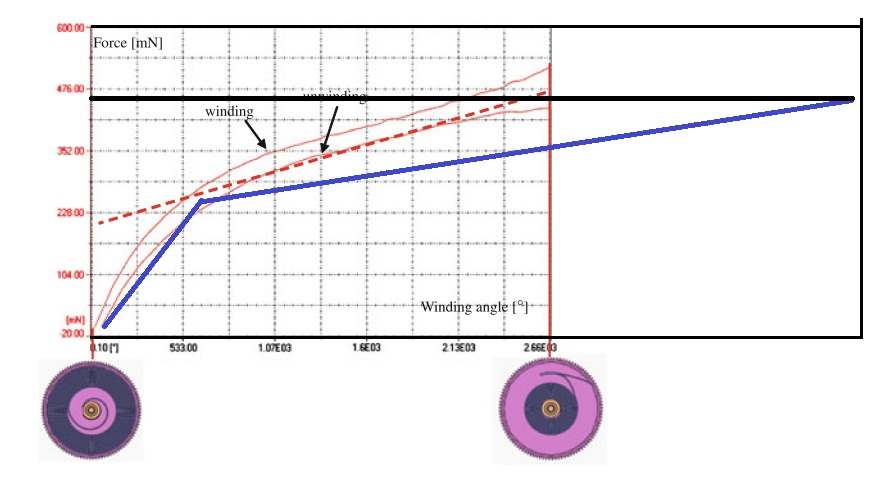

First, one has to consider the characteristic of the spring. The next diagram shows the spring force compared to winding angle (red lines, original spring). The new spring should have the same peak force (blue line) as the old one not to overstrain the gears. The geometry of the barrel hovewer determines the spring length. General rule according to DeCarle: Practical watch adjusting is to have 1/3 space for the spring couils, 1/3 open and 1/3 for the barrel arbor. Coil number of the spring (possible winding angle) can be increased only if the spring material is thinner. I can imagine that there are a newer and more modern spring steels those have the same strength but are thinner than old ones. But the problem is that we have even trouble to find original or similar springs to our watches. To find the required one for this problem seems impossible. And even if there is a source one need to shape the spring to fit in the barrel (make both end hooks). I dont think it worth the time to have +10-30 % more power reserve. On the other hand, manual wound watches are designed to wound every day at the same time. And by knowing your watch and with a daily routine they can be made incredibly accurate since the spring force changing every day the same amount.1 point

-

Finished my first two-part strap. For me a level up compared to the Nato-strap. The leather is 1.5mm veg.tanned cow, natural colour. The little-lugs had to be skived down to 1mm, glued and stitched together. Just like with forum member Hamish, because it's a custom made strap, only one-hole required The straps still look virgin, but through time, by aging and wearing, the leather will get darker and its rich patina. My first Nato-strap as comparison; (due to the bend in the strap, the holes look out of line, but they aren't) I'm closing off this thread and I hope that the above information will inspire you to make your own genuine leather straps......... or other leather articles. It gives a lot of satisfaction to make your own and you know exactly where it is made off Roland.1 point

-

Assuming that all of the pivots right the way through from the main spring barrel to the balance are scrupulously clean and correctly lubricated, your main candidates are; bent or badly worn pivot damaged teeth damaged jewel Any one of these (or any combination) anywhere in the train could cause the problem. I would strip it back down again, inspect all of the jewels and all of the pivots and teeth under good magnification and see if I could spot anything amiss. If not then the only route is to reassemble in stages and check the free running of the train at each stage. If there is a problem with intermittent power loss in the train then it will eventually come to light. The only other potential cause that I can think of would be a distorted main spring intermittently jamming in the barrel. You also need to check the main spring arbor in the barrel, and in the main plate and bridge pivots for freedom.1 point

-

I was bored and made up a watch from some of the junk I have. The case, no idea, a Seiko one and I'm not sure where I got it from. It's peculiar in that it's not a big watch but it's 22mm between the lugs. The movement is a mix bag of the 63XX series. I've added a whole heap of jewels, even the main spring Arbor is now riding on a couple. Final count 25 after the original 17. A 6309 7040 dial and hybrid hands (little aviation theme there) and a cheapo bracelet from the parts bin. It tested up real well and was an easy regulate. It is ticking away just fine and doesn't look too bad. It's a wearer.1 point

-

1 point

-

1 point

-

1 point

.thumb.jpg.e99604060c018974cedb994bb52df958.jpg)